Project Management Step by Step Proccess

An experienced team leads the way in designing and commissioning of solar systems for domestic and industrial requirements. Everything you need is taken care of – right from rooftop to ground mounted as well as solar park (open access) variants. Our qualified team studies the existing facility, evaluates potential area with a detailed review and analysis of space, angles, radiation, direction, structural loads, fitting types and safety measures required at the site. This ensures optimum solar energy generation with best space utilization. We offer solutions with zero upfront investment, zero maintenance obligations, and guaranteed Savings from day one! Step-by-Step Project Management Process

-

Step 1

Conceptualisation

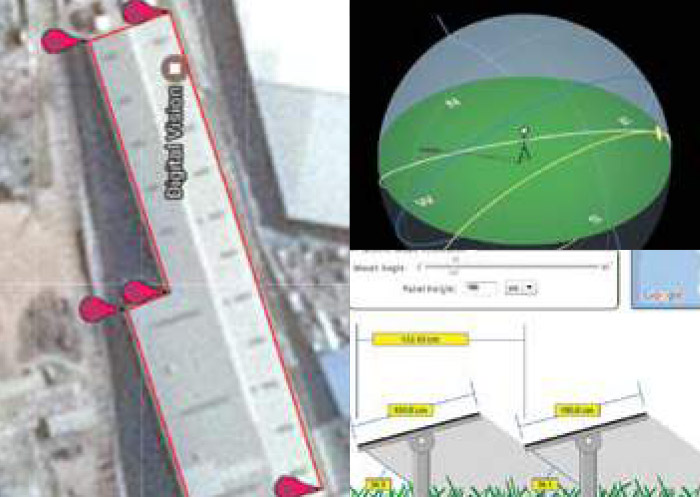

The first step is to do a complete and comprehensive study of the site The following parameters are studied

- Geographical location

- Available area and net solar yield

- Type of Area

- Roof(Abestos/RCC/GI)

- Ground

- Strength of the area

- Structural load and shadow analysis

- Electrical Design of the facility

- Safety protocols

Finally, a report is prepared and shared with the client for analysis

-

Step 2

Pre-feasibility Study

Feasibility Study covering radiation levels, estimated generation basis site condition, shadow analysis, structural design, and review of multiple layouts to optimize the space and maximize the production.

-

Step 3

Contract / Order

Documentation of plant energy output and system availability.

Clear commitment of performance, guarantees and signing of long term (upto 25 years) O&M with order itself

-

Step 4

Engineering / Design

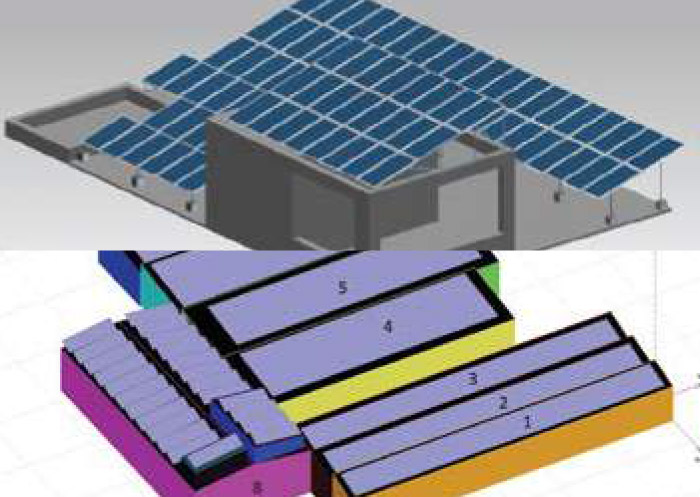

- Designing the solar PV plant

- Final layout and BOM is prepared

- Approvals

- MNRE/CEI/Discom process starts

-

Step 5

Legal Approval & Compliances

- State EDA Registration

- CEI Drawing Approval

- DISCOM Grid Connectivity Application

- DISCOM Grid Connectivity Agreement

- Bi-directional meter Purchase

- Bi-directional Meter Test

- CEI Inspection & Charging Certificate

- DISCOM Meter Installation & Report

- State EDA Commissioning Report

-

Step 6

Planning

- Single-point responsibility

- Fixed cost of project

- Timely completion within budget

- Achievement of performance guarantees

- Project management and planning

- Safety programs

-

Step 7

Procurement

Material procurement, unloading, safety and planning basis Gantt chart before start of execution.

-

Step 8

Installation

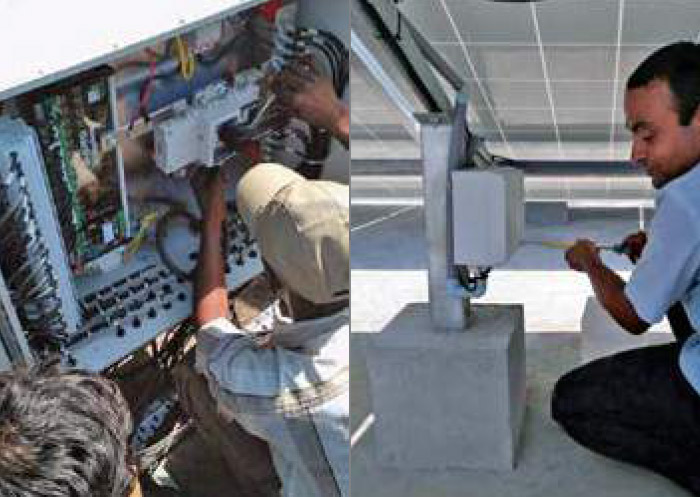

Professionally qualified and experienced team to execute and install project

Government approved engineers and contractors to complete structure mounting, PV modules installation, DC & AC cabling, Installation of SCB, Inverter, Transformer, VCB with good engineering practices

Power integration with Grid – Utmost safety protocols and with 100% legal compliance

Safety rails, walkways for regular cleaning, sufficient area for future maintenance, no compromise in quality

-

Step 9

Testing & Approval from State Authorities

- Bi-directional Meter Test

- Test reports and inspection of Inverters , VCB, SCB, Transformer, PV Modules

- Charging certificates from CEI office and Grid approvals and meter installation

-

Step 10

Handover

No compromise on standards, safety or quality even at the cost of financial impact.

CERC compliant plant design, highest standard of equipment and controls used for reliable systems.

-

Step 11

Operations & Maintenance

- Plant energy monitoring and recording at string level.

- Daily, weekly and monthly performance data monitoring.

- Daily analysis and evaluation of operational plant data through remote monitoring.

- Function check after fault message is received.

- Preventive inspection and maintenance of system components according to manufacturers’ specifications.

- Analysis of interruptions and incidents.

- Detailed information about main events and measures.

- Documentation of plant energy output and system availability.

- Long-term trend analysis.

- Thermo graphic inspection of complete electrical system during predictive maintenance.

- Specialized predictive maintenance on inverters.

- High-pressure module cleaning system-site specific.

- Troubleshooting 24×7.

- Inspection and maintenance works at regular intervals.

- Scheduled and predictive maintenance as recommended by the manufacturer.

- Report to customer for energy generation, energy pattern and executive report interaction.

Solar Plant Implementation Process

Site Analysis

Design & Engineering

Measurement & Marking

Structure & Module Mounting

Lightening Arrestor & Earthing

Electrical Cabling

Inverter, Transformer & Breaker

Power Integration – Grid & Load